In the digital age, USB cables play an indispensable role, whether it is charging or data transmission, we always need them. However, have you ever wondered about their outerwear, aka jacket materials, and the differences between those materials? Just like choosing clothing, choosing the right jacket material can also make your USB cable perform well in different situations.

In this blog, we will deeply explore the three USB cable jacket materials, TPE, PVC and nylon braid, and reveal their respective characteristics and applications for you. We hope that in this “fashion show” of the digital age, you will be wiser in choosing the USB cable that best suits your needs. Let’s explore this interesting topic together!

USB Cable Jacket Material Features: TPE/PVC/Nylon Brai.

The quality of a good USB data cable is built by the jacket material, the port (connector type and transmission protocol) and the copper core material. Click to learn more about the USB cable structure and wiring diagram. USB cable jacket materials play a vital role in affecting cable performance and durability.

Below is a detailed explanation of each common cable jacket material to help you better understand them and when you should choose which one.

TPE (Thermoplastic Elastomer)

TPE is a jacket material with both elasticity and durability. Its flexibility makes TPE cables suitable for mobile devices and charging scenarios, while the abrasion resistance can prolong the service life of the cables. TPE is the largest and fastest growing environmental thermoplastic elastomer material in the world. Can replace PVC and soft vulcanized rubber. The performance requirements and applications of elastomers used in wires and cables are mainly low voltage or DC, communications and other flexible wires. At the same time, TPE material has less impact on the environment and is an environmentally friendly choice. Often used for high quality USB cable jackets. It has the following characteristics:

- Flexibility: The TPE cable jacket is very soft and easy to bend and fold. The data cable made of TPE feels smooth and non-sticky, and can achieve a matte or delicate surface of the data cable. Suitable for mobile devices and charging scenarios.

- Abrasion resistance: TPE material is wear-resistant, can withstand the pulling and friction in daily use, and prolong the life of the cable.

- Environmental protection: TPE is a renewable and recyclable material, with a halogen-free flame retardant V0 level, which plays a great role in safety and environmental protection.

- Anti-oxidation: By formulating the TPE formula, the aging resistance and anti-yellowing UV performance of the wire can be improved, and the service life of the product can be extended. TPE has strong antioxidant properties, low smoke, halogen-free, phosphorus-free, excellent oil resistance, weather resistance, aging resistance, flexibility resistance, ozone resistance and chemical resistance.

- Machinability: TPE material has excellent processing performance and can be prepared in various colors. The most common ones on the market are white or light gray.

PVC (Polyvinyl Chloride)

PVC material is excellent in terms of cost-effectiveness and insulating properties. It is affordable and suitable for mass production, while its good insulation properties protect the internal wires from outside interference. In addition, PVC has strong chemical corrosion resistance and is suitable for various environments. Its unique features:

- Cost-Effective: PVC is an affordable material suitable for high-volume production and able to offer competitive prices.

- Insulation performance: PVC has good insulation performance, which can protect the internal wires from external interference.

- Plasticity: PVC is easy to process into different shapes and colors, providing more design options.

Nylon Weave

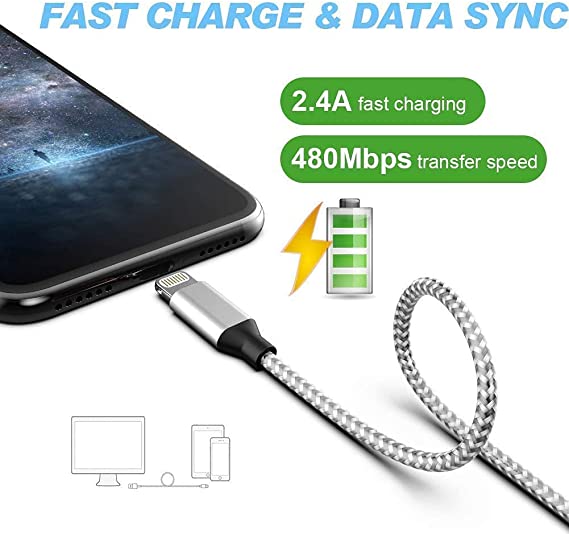

Nylon weave jacket material stands out for its durability and appearance. Its high strength enables the cable to withstand greater tension and pressure, and the braided appearance also adds to the fashion and modernity of the cable, which is deeply loved by fashion and individual users. Plus, the nylon braid reduces cable kinks and tangling issues.

Braided cables are an increasingly popular choice, especially for durability and aesthetic appeal:

- Durability:Nylon braided cable jacket is very strong, with high tensile strength, able to withstand greater pressure and tension.

- Anti-kink: Braided jacket reduces cable kinks and tangles, making cables easier to store and use.

- Appearance:The nylon braided jacket gives the cable a stylish and modern look, which is more visually appealing and is favored by personalized users.

| TPE, PVC VS Nylon braid performance comparison | |||

|---|---|---|---|

| Features | TPE | PVC | Nylon Braid |

| Wear resistance | Has good wear resistance; | Poor wear resistance, signs of wear will appear after long-term use; | Excellent wear resistance, suitable for outdoor and high-intensity use scenarios; |

| Flexibility | Excellent flexibility, suitable for bending; | Relatively rigid, less flexible; | Excellent flexibility and strong tensile strength; |

| Cold resistance | Remains flexible at low temperatures; | It is easy to become brittle and lose flexibility at low temperature; | It can maintain soft performance at low temperature and is suitable for outdoor use; |

| Chemical Resistance | Excellent resistance to salt spray, chemical and grease resistance; | May be sensitive to certain chemicals, use with caution; | Excellent resistance to salt spray, chemical and grease resistance; |

| Environmental protection | Recyclable, less waste in the manufacturing process; | The production process is likely to cause certain environmental problems; | Degradable, recyclable, good environmental performance; |

How to choose the right USB cable jacket material?

When you choose the right USB cable jacket material, there are some key factors to consider, as a professional customized USB cable factory, we offer you the following suggestions:

Determine the use and environment:

If your USB cable will be used outdoors, traveling, or in other highly active situations, a nylon braided jacket is usually a better choice because it can withstand more physical loss.

If your cable needs to work in a low temperature environment, make sure to choose a material with good low temperature resistance, such as TPE.

Length and bending frequency:

For long cables or cables that require frequent bending and stretching, choosing a material with high flexibility and durability, such as TPE or nylon braid, can reduce the risk of cable wear and tear.

Abrasion resistance and tensile strength:

If your cables are constantly plugged and pulled, a nylon braided jacket is an excellent choice because it can withstand greater physical stress.

Environmental considerations:

If you care about the environment, you can choose TPE material, because it is usually recyclable and produces less waste in the manufacturing process.

Customized requirements:

If you have special customized needs, such as specific color, printing or length, we as a professional manufacturer can meet your requirements.

Quality and Manufacturer Reputation:

Last but not least, choose a reputable manufacturer with excellent quality control measures to ensure that you get a high-quality USB cable.

To sum up, choosing the right jacket material for a USB cable requires a comprehensive consideration of multiple factors to ensure that your cable can provide a reliable connection and excellent performance in various situations. As a professional customized USB cable factory, we are committed to providing you with customized solutions that meet your needs.

In electronics, every detail counts, just like the clothing on an electronic device. Whether you’re looking for flexibility, durability, or aesthetic appeal, different USB cable jacket materials have their own unique benefits. When making your selection, you can consider your specific application, environmental conditions, and customer needs to ensure you choose the most suitable material. At APPHONE, we are well versed in the characteristics of different jacket materials, and can provide you with customized jacket materials and high-quality USB cable production to meet your customized needs, so as to ensure that your equipment achieves the best results in terms of performance and appearance. . If you are interested in our products and services, we always welcome you to contact us.