The Importance of Wire Gauge in USB Cables Explained.

Ever wonder what those numbers on USB cables mean? Like 24/32 AWG – what does it all refer to? The ratings actually tell you a lot about the cable’s thickness and capabilities.

USB cords have a wire gauge number, similar to speaker wire or electronic parts. This specifies the exact thickness of the internal copper wires. A thicker wire means a higher AWG number, while a thicker wire lowers the gauge.

This guide will explain what wire gauge ratings you’ll find on USB cords. We’ll break down the most common AWG numbers and how they impact data transfer speeds and the cable’s durability. Now you’ll know what makes a quality USB that can quickly charge devices and withstand many connections and bends over time.

What Is a Wire Gauge?

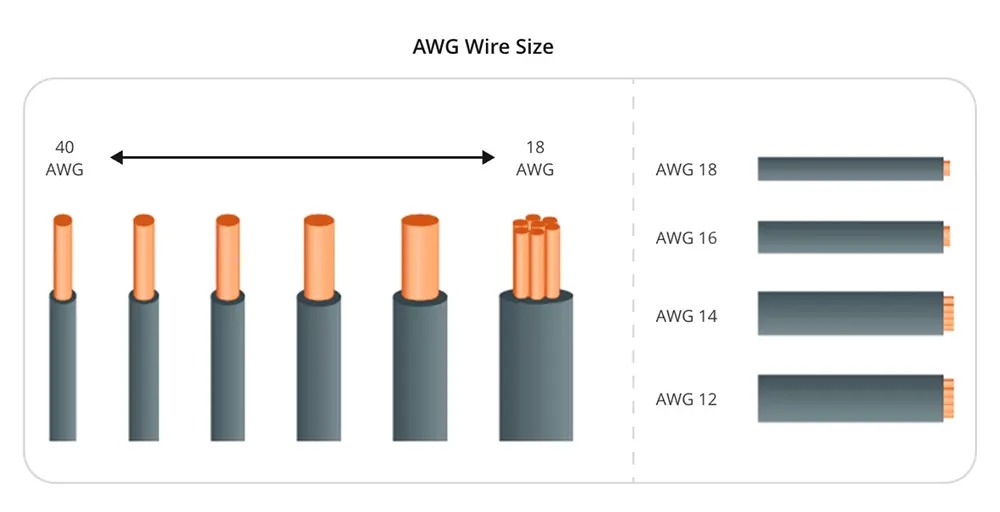

Wire gauge refers to the thickness of a wire, an essential factor in electrical applications. The gauge is denoted by a numerical value, where smaller numbers indicate thicker wires and larger numbers signify thinner ones. The most commonly used standard wire gauge in the United States is the American Wire Gauge AWG, which provides a systematic way to measure and identify the thickness of electrically conductive wires, primarily those made from non-ferrous materials.

Understanding wire gauge is crucial because the thickness of a wire directly influences its electrical properties, including resistance, current-carrying capacity, and overall efficiency in various applications. This knowledge is vital for professionals in the electrical and engineering fields, ensuring they select the right wire for specific tasks.

American Wire Gauge (AWG).

The American Wire Gauge system was developed to standardise wire sizes for electrical applications. It is particularly useful for specifying gauges for round and solid wire. Each gauge in the AWG system corresponds to a specific diameter and resistance, which helps professionals assess the appropriateness of a wire for a given application.

Birmingham Wire Gauge (BWG)

The Birmingham Wire Gauge (BWG) is a wire gauge system primarily used in the United Kingdom, particularly for measuring the diameter of wires and tubing. Developed in the 19th century, BWG provides a standardized method to specify wire sizes, which is crucial for manufacturers and engineers in ensuring compatibility and safety in electrical and mechanical applications. The BWG system assigns a numerical value to each wire diameter, where a lower number corresponds to a thicker wire. This system is especially prevalent in industries that require precise specifications for wire products, such as in the production of metal components and electrical installations. BWG is particularly useful for materials like copper and steel, providing a consistent framework that aids in the selection of the right wire for various applications, ensuring both performance and reliability.

Standard Wire Gauge (SWG)

The Standard Wire Gauge (SWG) is another wire gauge system used in the UK, primarily for non-ferrous materials. Similar to BWG, SWG assigns numerical values to wire sizes, facilitating a clear understanding of wire dimensions for professionals in engineering and manufacturing. The SWG system is particularly important for applications involving materials such as aluminum, brass, and copper, where precise wire thickness is critical for performance and safety. The SWG gauge numbers are also inversely related to wire thickness, meaning that a lower number signifies a thicker wire. This standard allows for a wide range of applications, from electrical wiring to the creation of various metal products. By using SWG, manufacturers can ensure that they adhere to established guidelines, resulting in better quality control and compatibility across different components and systems.

Relationships Between Wire Gauge and Other Technical Specs.

The AWG system provides a comprehensive understanding of a wire’s properties beyond just its thickness. Here’s how gauge relates to other technical specifications:

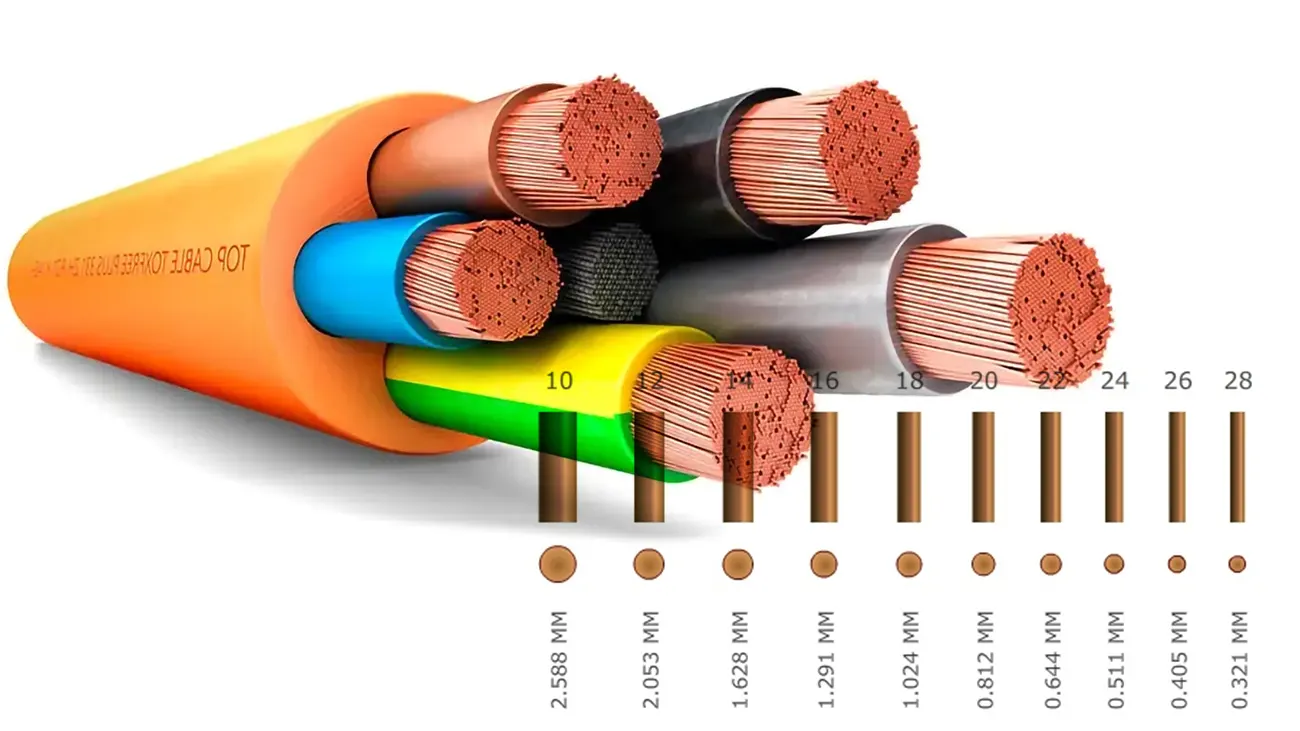

- Diameter:The diameter of a wire decreases as the gauge number increases. For example, AWG 4 wire has a diameter of 0.2043 inches, while AWG 40 wire has a diameter of 0.0031 inches. There’s a consistent relationship: the diameter doubles every time the gauge decreases by six levels. This means an AWG 3 wire has twice the diameter of an AWG 9 wire.

- Cross-Sectional Area: The cross-sectional area of a wire is the area of the circle formed by its diameter. It’s calculated using the formula: A = πr², where ‘r’ is half the diameter. The cross-sectional area doubles every time the gauge decreases by three levels. For example, an AWG 6 wire has double the cross-sectional area of an AWG 9 wire.

- Feet per Pound: This refers to the length of wire required to make up one pound of weight. Thicker wires have lower feet per pound, meaning a shorter length is needed to reach one pound. For example, AWG 4 wire requires 7.918 feet per pound, while AWG 40 wire requires 34.364 feet per pound.

- Resistance (Ohms per 1000 feet): Resistance is the opposition to the flow of electrical current. Thicker wires have lower resistance. For example, at 25°C, AWG 4 wire has a resistance of 0.2485 ohms per 1000 feet, while AWG 40 wire has a resistance of 1079 ohms per 1000 feet.

- Current Capacity (Amps): Current capacity refers to the maximum amount of current a wire can safely carry. Thicker wires have higher current capacity due to their larger cross-sectional area, which allows for more electrons to flow. For example, AWG 4 wire can handle significantly more current than AWG 40 wire.

Wire gauge is a fundamental concept in electrical engineering and plays a vital role in ensuring the safe and efficient operation of electrical systems. We just saw the relationships between wire gauge and other technical specifications, which means it is essential for selecting the right wire for any given application.

Complete Wire Gauge Table.

In this section, we will provide you with a complete wire gauge table. This Wire Gauge Table is a super helpful reference for anyone working with electrical wires. It lists all kinds of wire sizes along with their thickness in both inches and millimetres. Electricians, engineers, and DIY folks will get a lot of use out of this. Whether you need big wires for heavy construction or small ones for electronics, this table makes choosing the right gauge simple.

| Gauge | Inches | Millimeters | AWG | SWG | BWG | Circular Mils |

|---|---|---|---|---|---|---|

| 1 SWG | 0.300000 | 7.62000 | 1 | 1 | 1 | 89,997.415200 |

| 1 BWG | 0.300000 | 7.62000 | 1 | 1 | 1 | 89,997.415200 |

| 1 AWG | 0.289300 | 7.34822 | 1 | 1 | 1 | 83,692.086294 |

| 2 BWG | 0.283000 | 7.18820 | 2 | 2 | 2 | 80,086.699844 |

| 2 SWG | 0.276000 | 7.01040 | 2 | 2 | 2 | 76,173.812225 |

| 1.5 AWG | 0.273003 | 6.93428 | 1.5 | 2 | 2 | 74,528.497489 |

| 3 BWG | 0.259000 | 6.57860 | 2 | 3 | 3 | 67,079.073434 |

| 2 AWG | 0.258000 | 6.55320 | 2 | 2 | 3 | 66,562.088282 |

| 3 SWG | 0.252000 | 6.40080 | 2 | 3 | 3 | 63,502.176165 |

| 2.5 AWG | 0.243116 | 6.17515 | 2.5 | 3 | 4 | 59,103.691949 |

| 4 BWG | 0.238000 | 6.04520 | 3 | 4 | 4 | 56,642.373184 |

| 4 SWG | 0.232000 | 5.89280 | 3 | 4 | 4 | 53,822.454175 |

| 3 AWG | 0.229000 | 5.81660 | 3 | 4 | 5 | 52,439.493894 |

| 5 BWG | 0.220000 | 5.58800 | 3 | 5 | 5 | 48,398.609952 |

| 3.5 AWG | 0.216501 | 5.49913 | 3.5 | 4 | 6 | 46,871.336818 |

| 5 SWG | 0.212000 | 5.38480 | 4 | 5 | 5 | 44,942.709208 |

| 4 AWG | 0.204000 | 5.18160 | 4 | 5 | 6 | 41,614.804788 |

| 6 BWG | 0.203000 | 5.15620 | 4 | 6 | 6 | 41,207.816478 |

| 4.5 AWG | 0.192800 | 4.89712 | 4.5 | 6 | 7 | 37,170.772425 |

| 5 AWG | 0.182000 | 4.62280 | 5 | 7 | 7 | 33,123.048679 |

| 7 BWG | 0.179000 | 4.54660 | 5 | 8 | 7 | 32,040.079782 |

| 5.5 AWG | 0.171693 | 4.36100 | 5.5 | 7 | 8 | 29,477.639627 |

| 8 BWG | 0.164000 | 4.16560 | 6 | 8 | 8 | 26,895.227547 |

| 6 AWG | 0.162023 | 4.11538 | 6 | 7 | 8 | 26,250.698587 |

| 6.5 AWG | 0.152897 | 3.88358 | 6.5 | 9 | 9 | 23,376.821207 |

| 9 BWG | 0.147000 | 3.73380 | 7 | 9 | 9 | 21,608.379390 |

| 20 AWG | 0.032000 | 0.81280 | 20 | 21 | 21 | 1,023.970591 |

How Does Wire Gauge Impact USB Cable Performance?

The wire gauge of a USB cable significantly influences its performance regarding charging and data transfer capabilities. Understanding this relationship is crucial for selecting the right cables for various applications.

Current Carrying Capacity

The wire gauge directly influences how much current a USB cable can safely carry. Thicker wires (indicated by lower gauge numbers) have a larger cross-sectional area, which allows them to handle higher currents without overheating. For instance, an AWG 20 cable can typically support up to 5 amps, while an AWG 28 cable may only handle around 1.5 amps. This difference is crucial for devices that require rapid charging.

Voltage Drop

As current flows through a wire, some energy is lost as heat, resulting in voltage drop. Thicker wires reduce this voltage drop, which is especially important for longer cables. A cable that is too thin may lead to insufficient voltage reaching the device, causing slower charging speeds or even preventing the device from charging altogether. For instance, a 1-metre AWG 20 cable will perform significantly better than a 2-metre AWG 28 cable in terms of voltage drop and charging efficiency.

Data Transfer Rates

Wire gauge also affects the ability of a USB cable to transmit data efficiently. Thicker wires can support higher frequencies, which are essential for achieving faster data transfer rates. For example:

- USB 2.0 supports data transfer speeds up to 480 Mbps.

- USB 3.0 can reach speeds up to 5 Gbps or more.

Using a thicker gauge wire helps maintain the integrity of the signal over longer distances, reducing interference and ensuring reliable data transmission.

Signal Integrity

Signal integrity is vital for data transmission, especially in high-speed applications. Thicker wires help minimise resistance and capacitance, which can distort the signal. This is particularly important for tasks like streaming video or transferring large files, where data integrity is essential. A cable that uses a thinner gauge may introduce errors in data transmission, leading to slower speeds or dropped connections.

As we can see, wire gauge significantly impacts USB cable performance in both charging and data transfer capabilities. Thicker wires allow for higher current carrying capacity and reduce voltage drop, leading to faster charging. They also support higher frequencies and maintain signal integrity, ensuring reliable data transmission. When choosing USB cables, it’s essential to consider wire gauge alongside other factors to achieve the best performance for your devices.

Commonly Used Wire Gauge Parameters For USB.

To help you choose the right gauge for your needs, I’ll include a detailed chart listing common wire gauges from AWG 34 to 20. You’ll see each size’s maximum current capacity so you can match the gauge to your power requirements. First let’s look at the detail of each type of gauge.

1. 34 AWG

34 AWG has an extremely thin diameter of just 0.255mm, making it very flexible but also limiting. It consists of narrow single-strand copper wiring, has a low maximum current rating of around 0.5A and is only suitable for short, simple data transfers. It struggles to reliably carry even moderate charges and isn’t robust enough for frequent movement.

2. 32 AWG

32 AWG is slightly thicker at 0.280mm diameter compared to 34 AWG. It typically uses multi-strand rather than single-strand copper wire. It can support basic 500mA USB 2.0 spec but performance suffers over longer cable lengths, making it suitable for lightweight mobile device data cables.

3. 30 AWG

30 AWG provides a modest boost in conductivity with its 0.310mm diameter. It has a maximum current rating of around 1A, allowing reliable 1A USB charging over short runs under 3 feet. It’s often used in lightweight auxiliary audio cables in addition to basic USB duties. However, it still has limitations and isn’t meant for demanding high-power applications.

4. 28 AWG

28 AWG has a diameter of 0.365mm, making it slightly thicker than 30 AWG and allowing improved current carrying capacity over thinner wires. It represents a good balance for most basic consumer applications, supporting 1A/5V charging and USB 2.0 data transfer speeds. Commonly found in shorter cables under 3m used with smartphones and portable chargers.

5. 26 AWG

26 AWG has a diameter of 0.410mm, noticeably thicker than 28 AWG and with nearly 15% higher current rating, making it ideal for accessories with higher power needs like portable speakers and hard drives. It allows 1A/5V charging over longer cable runs while also supporting faster USB 3.0 data transfer speeds. Frequently used in Micro USB cables, battery packs, and emergency jump starters.

6. 24 AWG

24 AWG has a diameter of 0.511mm, almost 40% thicker than 28 AWG and doubling its maximum current capacity. This enters the “heavy duty” category, suiting it for power-hungry devices. It reliably charges laptops and supports faster protocols like Quick Charge. Durable enough for demanding professional audio/video applications and industrial use.

7. 22 AWG

22 AWG has a diameter of 0.643mm, providing the best conductivity for virtually any USB application. When paired with high-quality plating, it can withstand 100W Power Delivery standards. It has industrial-grade durability for continuous, high-load operations, making it ideal for scenarios involving heavy machinery control and commercial equipment.

8. 20AWG

20 AWG is one of the thicker wire gauges used before industrial levels. With a diameter of 0.8128mm, it offers superb conductive abilities. This gauge provides truly exceptional power delivery, handling high loads with minimal losses.

Let’s look at wire gauge amp chart summarising the American Wire Gauge AWG ratings from 34 AWG down to 20 AWG, along with their maximum current capacities:

| AWG Rating | Maximum Current Capacity |

|---|---|

| 34 AWG | Up to 0.25 A |

| 32 AWG | Up to 0.5 A |

| 30 AWG | Up to 0.5 A |

| 28 AWG | Up to 0.9 A |

| 26 AWG | Up to 1.2 A |

| 24 AWG | Up to 2.1 A |

| 22 AWG | Up to 3.0 A |

| 20 AWG | Up to 5.0 A |

This chart provides a clear overview of the wire gauge ratings and their corresponding maximum current capacities, which is essential for selecting the appropriate wire gauge for your electrical needs.

It’s crucial to emphasize the quality assurance of wire gauge control and selection in the USB manufacturing process. At APPHONE, we implement rigorous quality control measures to ensure that every wire meets the specified gauge standards. This commitment to precision and quality helps us deliver USB cables that perform consistently under various conditions, providing our customers with confidence in their connectivity solutions.

What gauge wire for 30 amp?

A wire gauge for 30 amp is 10 gauge wire. This gauge provides adequate conductivity and reduces the risk of overheating, especially over longer distances. Using a thicker wire ensures safety and compliance with electrical codes, which is critical in preventing potential electrical hazards.

What gauge wire for 50 amp?

In the case of gauge wire 50 amp, you should use 6 gauge wire. This wire size can handle the increased current safely, minimising voltage drop and heat generation. It is essential to select the correct gauge to ensure that the circuit operates efficiently and within safe limits, particularly for high-power applications like electric ranges or large tools.

What gauge wire for 20 amps?

For a 20 amp circuit, a 12 gauge wire is appropriate. This wire size is sufficient for residential wiring, including lighting circuits and receptacles. Using a 12 gauge wire helps to ensure that the circuit can handle the current without overheating, which is crucial for maintaining safety and preventing electrical fires.

What gauge wire for 15 amp?

For a 15 amp circuit, you can use 14 gauge wire. This wire gauge is commonly used for general-purpose circuits, such as lighting and outlets. It provides the necessary capacity for a 15 amp load while ensuring that the wire does not heat excessively, which is important for electrical safety.

What gauge wire for 40 amp?

For a 40 amp circuit, it is best to use 8 gauge wire. This gauge is suitable for applications like hot tubs, electric vehicle chargers, and other high-demand equipment. Properly sizing the wire is crucial to ensure that it can handle the load without risk of overheating or voltage drop, thus maintaining system reliability.

What gauge wire for 100 amp?

For a 100 amp service, a 3 gauge wire is typically recommended. This wire size is essential for main service feeds and larger electrical systems. Choosing the correct gauge helps ensure that the wire can safely conduct high current levels, preventing overheating and ensuring that the electrical system operates efficiently.

What gauge wire for 60 amp?

For a 60-amp circuit, a 4 AWG battery cable is often recommended. This size ensures the cable can safely handle the current without overheating, thus maximising system efficiency and safety.

Share This Artcle:

Fast delivery

Fastest delivery within 22 days

Quick proofing

Fastest 3-day proofing cycle

After-sale protection

24-month long warranty

1V1Customer Service

Professional customer service follow-up