VW-1 and CSA Flame Tests Description Guide

As we know, these days ensuring the safety of USB cables is paramount, especially as they are widely used in various applications, from charging devices to data transfer. Understanding flame retardant standards, such as the CSA flame tests and VW-1, is crucial for manufacturers and consumers alike. These standards determine how well cables can resist ignition and prevent the spread of fire, making them essential for compliance and safety. So, let’s find out the differences between CSA flame tests and VW-1 ratings, and their importance in the selection of reliable and safe USB cables. Also, we will see how these standards impact your choices and what to look for when purchasing cables to ensure optimal safety.

What is the Flame Retardant Rating Of Cables?

The flame retardant rating of cables is a critical aspect of electrical safety, indicating a cable’s ability to resist ignition and prevent the spread of fire. This rating is often determined through testing standards such as UL 94, which classifies materials based on their flammability characteristics. Cables with a V-0 rating are considered highly flame retardant, meaning they will extinguish within 10 seconds after being ignited and will not produce flaming droplets. A V-1 rating indicates that the material will extinguish within 30 seconds, but may produce some droplets that do not ignite cotton. Conversely, a V-2 rating allows for longer extinguishing times and may produce flaming droplets that can ignite cotton.

Selecting cables with appropriate flame retardant ratings is crucial, especially in applications where fire safety is paramount, such as in residential, commercial, and industrial settings. These ratings help prevent electrical fires and protect both people and property. Reliable Manufacturers, like APPHONE, prioritize the use of materials that meet these stringent flame retardant standards to ensure the safety and reliability of their products, ultimately providing peace of mind to consumers.

What is the VW-1 Flame Test?

The VW-1 flame test, or Vertical Wire-Class 1 flame testing, is a crucial safety evaluation method developed by Underwriters Laboratories (UL) to assess the flammability of electrical cables and wires. This test is designed to identify materials that may pose a fire hazard under specific conditions, ensuring that only safe products reach consumers. The purpose of the UL VW-1 Vertical Wire Flame Test is to screen out flammable wires. The ignition source is small (under 1 kW) and is applied for only 75 seconds. In the UL VW-1 Flame Test, a tirrill burner (similar to a Bunsen burner) is used as the ignition source. A wire sample is mounted vertically above a Bunsen burner, serving as the ignition source. The wire is subjected to flames in 15-second intervals, repeated five times for a total of 75 seconds of exposure. The criteria for passing are strict: if the wire burns for more than 60 seconds or if over a quarter of the sample is consumed, it fails. Additionally, the burner’s base is stuffed with cotton; if the cotton ignites during testing, the sample also fails.

How Do CSA Flame Tests Differ from VW-1?

CSA Flame Tests and VW-1 tests are distinct methods for evaluating the flammability and fire safety of materials, particularly for electrical cables. CSA standards are safety standards in Canada for electrical appliances, medical devices, machinery, equipment, etc. The Canadian Standards Association was established in 1919 as a non-profit, non-governmental standardization organization. Today, the CSA Group encompasses both the CSA, which focuses on standards development, and CSA International, which handles product testing and certification.

The primary purpose of CSA standards is to ensure the safety of electrical products. In Canada, laws mandate that all electrical machinery and appliances connected to power sources must conform to CSA safety standards, regardless of their type or quantity. Consequently, compliance with these standards is not merely recommended; it is a legal requirement for applicable products across all provinces and territories.

While CSA standards are developed voluntarily by its members, many have been formally adopted as Canadian national standards. These standards are referenced in various laws and regulations by national and provincial governments, ensuring broader compliance. Standards that have achieved this status are identified with a prefix code of “CAN,” such as CAN/CSA C22.1.

In contrast, the VW-1 test, established by Underwriters Laboratories (UL) in the United States, focuses on evaluating the fire resistance of cables when exposed to flames in a vertical position. This test involves exposing a cable sample to a controlled flame for a specific duration to assess its ability to resist burning and self-extinguish. The VW-1 test is part of UL’s broader suite of fire safety standards and is used to ensure that cables meet safety and performance criteria, with applications spanning various environments in the United States and internationally.

The primary objective of the VW-1 test is to assess the flame resistance of cables in vertical installations, which is a common orientation in real-world scenarios such as conduit systems, cable trays, and vertical risers in buildings. The test ensures that cables are capable of withstanding direct flame exposure without contributing significantly to fire spread. It helps in preventing the cable from acting as a conduit for fire, thereby enhancing overall building safety.

VW-1 testing is part of the broader UL certification process, which ensures that products meet established safety and performance standards. Cables that pass the VW-1 test are considered suitable for use in applications where fire safety is a critical concern. This includes residential, commercial, and industrial environments, where the reliability of electrical wiring is paramount to preventing fire hazards.

The VW-1 test is widely recognized in the United States and is referenced in various codes and standards, including the National Electrical Code (NEC). It is an essential certification for manufacturers seeking to demonstrate that their products meet stringent fire safety requirements. In addition to its use in the U.S., VW-1 standards are often adopted internationally, making it a significant benchmark for fire safety in electrical cables globally.

Classification of CSA Standards

CSA standards are categorized into nine major groups, reflecting diverse sectors:

- Lifestyle and Environment

- Environmental Engineering

- Electricity and Electronics

- Communications and Information

- Construction

- Energy

- Transport and Distribution

- Material Engineering

- Commercial and Production Management Systems

Within these categories, over 1,500 different standards have been developed and published, addressing various safety and performance requirements.

CSA Flame Test Ratings: FT1, FT2, FT4, and FT6

FT1, FT2, FT4, and FT6 are flammability ratings for cables that comply with CSA wire flammability standards. Each test evaluates different aspects of fire resistance, determining the suitability of cables for various applications.

FT1 Flame Test:

The FT1 flame test is a crucial assessment for electrical cables, determining their resistance to vertical flames. In this test, the cable is subjected to a flame at a rate of 3,000 BTU/hour for 15 seconds, and this exposure is repeated five times. The purpose of the FT1 test is to evaluate how well the material can withstand ignition and prevent flame propagation when oriented vertically, which is a common scenario in many installations.

During the test, the cable is monitored for ignition and the duration of any burning that occurs. If the material ignites, the burn duration is recorded, and the extent of flame spread is evaluated. The results help indicate the cable’s suitability for applications where vertical flame resistance is critical, such as in residential, commercial, and industrial settings. Cables that pass the FT1 test are deemed safe for use in environments where there is a risk of fire spreading from the cable to other materials.

This test is particularly important as it aligns with safety regulations, ensuring that products meet the necessary standards to protect against fire hazards. Cables designed for use in walls, ceilings, or other vertical installations must demonstrate reliable performance under these conditions to minimize risks.

FT2 Flame Test

The FT2 flame test is designed to evaluate the flammability of cables in a horizontal orientation, making it one of the easier tests to pass. In this test, a horizontal sample of the cable is exposed to a flame at a rate of 1,700 BTU/hour for 30 seconds. The FT2 test assesses the material’s reaction to fire and its ability to limit flame spread in less hazardous situations.

During the test, the main focus is on whether the cable ignites and how quickly it extinguishes once the flame source is removed. Because FT2 represents the lowest level of flame retardancy among the tests, it is often suitable for flexible cables used in applications where fire risk is minimal. Examples include temporary installations or environments where the cables are not permanently fixed.

Cables that meet FT2 standards are commonly found in consumer electronics, appliances, and other applications where stringent fire resistance is not as critical. While passing the FT2 test indicates a certain level of safety, it is essential for manufacturers to ensure that these cables are used appropriately, in line with local electrical codes and safety regulations.

FT4 Flame Test

The FT4 flame test is a rigorous assessment used to evaluate the flammability of cables in vertical configurations. In this test, a cable sample is positioned in a vertical tray and subjected to a flame exposure of 70,000 BTU/hour for a duration of 20 minutes. The primary objective is to determine the material’s ability to resist ignition and prevent flame propagation under severe conditions.

During the FT4 test, the cable is closely monitored for any signs of scorching or burning. A key criterion for passing is that there should be no scorching within 59 inches of the flame. This indicates that the material can withstand prolonged exposure to fire without significantly degrading or contributing to fire spread. Cables that pass the FT4 test are suitable for installation in non-flammable buildings and environments where enhanced flame resistance is essential, such as in high-rise structures, tunnels, and commercial facilities.

The FT4 test is particularly important for ensuring safety in applications where fire hazards are a concern. By demonstrating a high level of flame resistance, cables passing this test help protect both property and occupants from the dangers of fire.

FT6 Flame Test

The FT6 flame test represents an advanced evaluation of cable materials, focusing on flame spread and smoke production in a horizontal orientation. In this test, the cable is subjected to a specific flame exposure while adhering to a maximum flame spread limit of 4.92 feet. To pass, the cables must conform to ANSI/NFPA Standard 262-1985 (UL-910), which outlines criteria for both flame spread and smoke emissions.

During the FT6 test, the cable is ignited in a controlled environment, and the flame spread is carefully measured. The emphasis is not only on how quickly the material ignites but also on how far the flame can travel along the cable’s length. Additionally, the test assesses the quantity of smoke produced, as excessive smoke can pose significant hazards during a fire event.

Cables that pass the FT6 test are typically used in commercial and industrial applications where fire safety is critical. This includes environments such as airports, shopping malls, and high-rise buildings, where both flame spread and smoke production can greatly impact safety during emergencies. Meeting FT6 standards ensures that materials contribute to a safer environment by limiting fire hazards and enhancing visibility for evacuation.

Other CSA Standards Related to Electrical Safety

CSA standards pertaining to electrical safety are primarily identified by the standard numbers C22.1 and C22.2, which together form the Canadian Electrical Code (CEC) Parts I and II.

- CAN/CSA C22.1 – Canadian Electrical Code Part 1

This standard outlines the safety regulations for electrical installations. It covers all aspects of indoor wiring, detailing the requirements from the service wire entering a consumer’s premises to the final connections for electrical loads, such as sockets and appliances. Compliance with C22.1 ensures that electrical installations are safe, reliable, and up to code. - CAN/CSA C22.2 Series – Canadian Electrical Code Part II

Part II consists of approximately 300 individual standards that address the safety of electrical machinery, appliances, and their components. These standards apply to devices connected to power sources that are wired according to the regulations set forth in Part I. This comprehensive framework ensures that all electrical equipment meets safety requirements before being used in residential, commercial, or industrial settings. - CAN/CSA C22.2 No. 0 – General Requirements

This standard includes general requirements that apply to the entire C22.2 series. It provides a foundational set of regulations that must be adhered to in conjunction with the individual standards within the series, ensuring consistency and safety across various electrical products. - C22.2 No. 0.0 Series

The C22.2 No. 0.0 series consolidates common testing methods, structures, and procedures applicable to the C22.2 standards. This ensures that testing is standardized across different types of electrical products, enhancing reliability and safety. - CAN/CSA-E Series

Specific products, such as SMC valves, fall under the C22.2 No. 139 standard, which pertains to electrically operated valves. This classification provides tailored requirements for the safe use of these components within electrical systems.

All these CSA standards related to electrical safety provide a robust framework for ensuring the safe installation and operation of electrical products in Canada, helping to mitigate risks associated with electrical hazards.

Comparison Of CSA And Vw-1 Standards.

CSA and VW-1 standards both play important roles in ensuring electrical safety, but they focus on different aspects.

| Aspect | CSA Standards | VW-1 Standards |

|---|---|---|

| Overview | Developed by the Canadian Standards Association; covers a wide range of electrical products and safety regulations. | Known as UL 1581; North American standard for flame retardancy testing of wire and cable insulation. |

| Purpose | Ensures safety and reliability of electrical products and installations in Canada. | Assesses the ability of insulation to resist the spread of fire in cables. |

| Testing Method | Involves various tests, including vertical and horizontal flame tests for different applications. | Conducts a vertical burning test to measure flame spread resistance. |

| Criteria for Passing | Cables must meet specific performance metrics, including ignition resistance and burn duration. | Cables must demonstrate minimal flame spread to be marked VW-1. |

| Scope of Application | Applies to a broad range of electrical equipment, including appliances and wiring. | Specifically for wire and cable insulation, indicating flame retardancy. |

| Regulatory Status | Legally required for applicable electrical products in Canada; compliance is mandatory. | Recognized standard in North America, but does not imply suitability for wall insulation. |

| Use Cases | Suitable for residential, commercial, and industrial applications with varying safety requirements. | Safe for use in applications requiring flame retardancy, but not suitable for all installations, such as wall insulation. |

How Do Different Flame Retardant Ratings Affect Cable Selection?

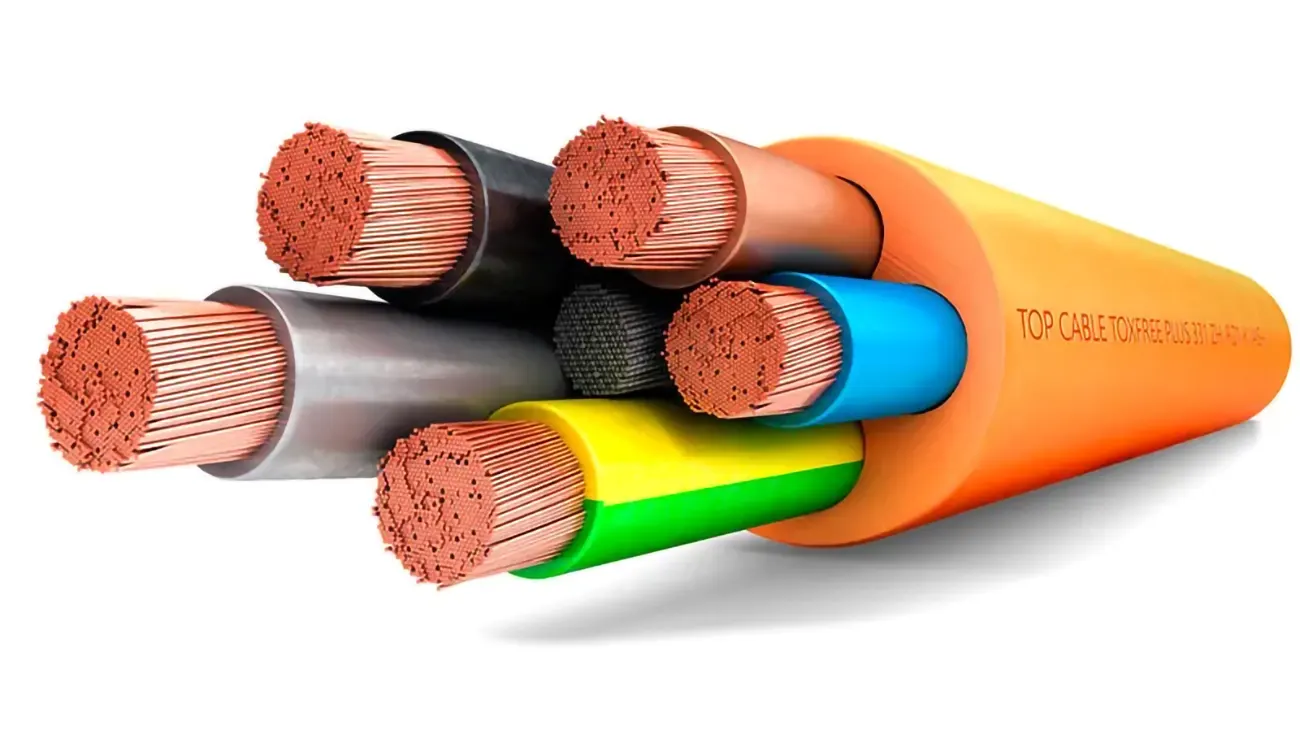

When selecting cables for various applications, understanding flame retardant ratings is crucial. These ratings, such as FT1, FT2, FT4, FT6, and VW-1, indicate how well a cable can resist ignition and prevent the spread of fire. Each rating reflects specific testing conditions and performance criteria, guiding manufacturers and consumers in making informed choices based on safety needs.

Flame retardant ratings directly influence the environments where cables can be safely installed. For instance, FT1 and FT2 ratings are often sufficient for flexible cables used in consumer electronics or in environments with minimal fire risk. These cables might be suitable for temporary setups or areas where they are unlikely to encounter direct flames. However, for more demanding applications, such as those found in commercial buildings or industrial settings, higher ratings like FT4 and FT6 become essential. These cables are designed to withstand significant exposure to fire, ensuring that they do not contribute to flame spread and provide critical time for evacuation.

Additionally, local and national electrical codes often dictate which ratings are required for specific installations. For example, cables installed within walls or ceilings typically need to meet stricter standards, like FT4 or VW-1, to comply with safety regulations. This ensures that the materials used can withstand potential fire hazards without posing additional risks.

Choosing the right flame retardant rating not only enhances safety but also impacts the overall performance and longevity of the cable. Higher-rated cables may be constructed with advanced materials that offer better durability and resistance to environmental factors. This can lead to reduced maintenance costs and fewer replacements over time.

How Can We Ensure that USB Cables Meet the Flame Retardant Standards?

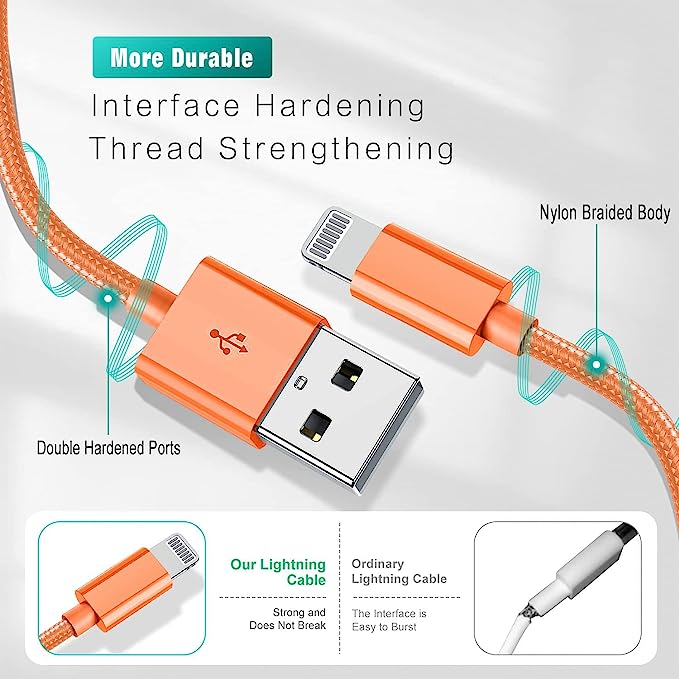

Ensuring that USB cables meet flame retardant standards involves a comprehensive approach that includes careful material selection, rigorous certification, and thorough testing. Here’s how these processes work together to achieve safety and compliance.

Outsourcing Material Selection

The first step in ensuring flame retardancy is selecting the right materials. When outsourcing the production of USB cables, it’s essential to collaborate with reputable suppliers who provide flame-retardant materials that meet established standards. Manufacturers should prioritize materials that have been specifically tested and certified for flame resistance, such as PVC, TPE, or other specialized compounds. Engaging with suppliers who understand the requirements of standards like FT1, FT2, FT4, and VW-1 is crucial for sourcing materials that enhance safety.

Certification

Once the materials are selected, the next step is certification. It’s vital to work with manufacturers that have the capability to conduct or facilitate certification through recognized testing laboratories. Certifications from organizations such as Underwriters Laboratories (UL) or the Canadian Standards Association (CSA) indicate that the cables have undergone rigorous testing for flame retardancy. This certification process not only ensures compliance with safety standards but also provides assurance to consumers about the reliability of the product.

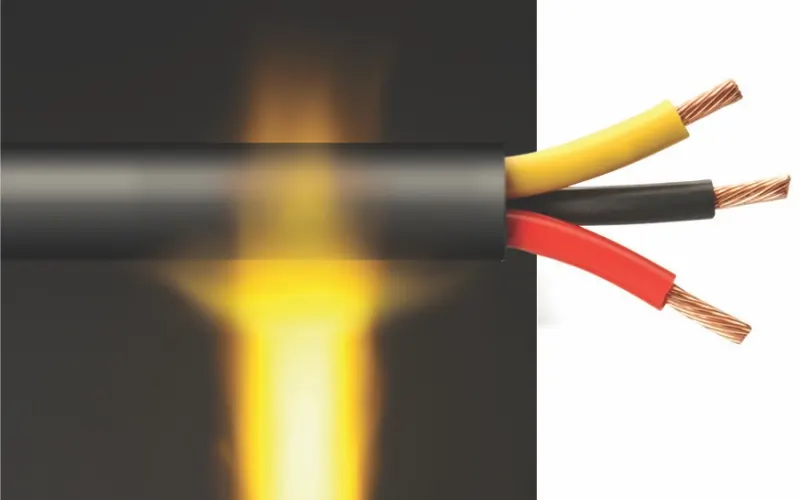

Testing

Thorough testing is key to validating that USB cables meet flame retardant standards. This involves conducting various flame tests, such as vertical and horizontal burn tests, to assess how well the cables resist ignition and flame spread. Manufacturers should implement a quality assurance program that includes regular testing of production samples to ensure consistent compliance with flame retardant ratings.

Additionally, ongoing monitoring and reassessment of materials and manufacturing processes are essential. As technology and materials evolve, maintaining compliance with the latest standards is crucial for safety. Reliable and reputable manufacturers make sure to have all these aspects in the cable production process. At APPHONE, we prioritize the safety and reliability of our USB cables through a meticulous approach to material selection and certification. We collaborate with trusted suppliers who specialize in flame-retardant materials, ensuring that all components meet the highest safety standards. Our rigorous certification process involves partnering with recognized testing laboratories, such as UL and CSA, to validate that our cables comply with essential flame retardant ratings.

Additionally, we conduct regular testing and quality assurance checks throughout the manufacturing process to maintain consistency and reliability. By adhering to these stringent practices, APPHONE guarantees that our USB cables not only meet regulatory requirements but also provide our customers with peace of mind, knowing they are using safe and dependable products.

What is the standard for fire retardant cable?

Two common standards are IEC 60332-1 and IEC 60332-2. IEC 60332-1 tests individual cables at an angle, while 60332-2 tests them vertically. IEC 60332-3 bundles multiple cables for vertical testing. These provide data on how cables burn in different scenarios.

What is the difference between IEC 60332-1 and UL?

The main difference is that cables meeting IEC specifications can continue burning to a degree while emitting minimal glasses. US tests like UL 1581, UL 1666 and UL 910 require the flame to fully extinguish, but gasses released are still monitored carefully.

What is the standard for flame-retardant tests?

These tests focus on weight loss and residual burning time. To pass, weight loss typically can’t exceed 40% of the initial sample weight. Remaining flames after testing should average less than 2 seconds. This helps gauge the material’s ability to resist burning.

What is the ASTM standard for fire resistance?

ASTM E119 is a common standard. It establishes methods to determine how long various construction elements can contain a fire, maintain structural integrity or both when exposed to controlled testing conditions in a furnace. This provides data on building material performance during fires.

What is the difference between flame retardant and fire resistant cables?

Flame retardant cables are designed to prevent or slow the spread of fire, while fire resistant cables are intended to maintain functionality for a specified time period during a fire exposure.

What is flame retardant grade?

There are 12 plastic grades under the UL94 standard – the main international classification system. It evaluates a material’s ability to self-extinguish once ignited, with lower grades indicating better flame resistant properties.

How to test flame retardant?

One common test method involves vertically exposing a sample to a hot gas burner at 1500°F for timed intervals. The flame spread and burn characteristics are evaluated against set criteria.

What are flammability standards?

Key standards include ASTM E84/UL 723 for flame spread on building materials, ASTM E162/UL 97 for flame propagation of floors, and ASTM E648/NFPA 253 for critical radiant flux levels. Standards provide objective ways to assess and classify fire performance.

Share This Artcle:

Fast delivery

Fastest delivery within 22 days

Quick proofing

Fastest 3-day proofing cycle

After-sale protection

24-month long warranty

1V1Customer Service

Professional customer service follow-up